About used horizontal lathe machine

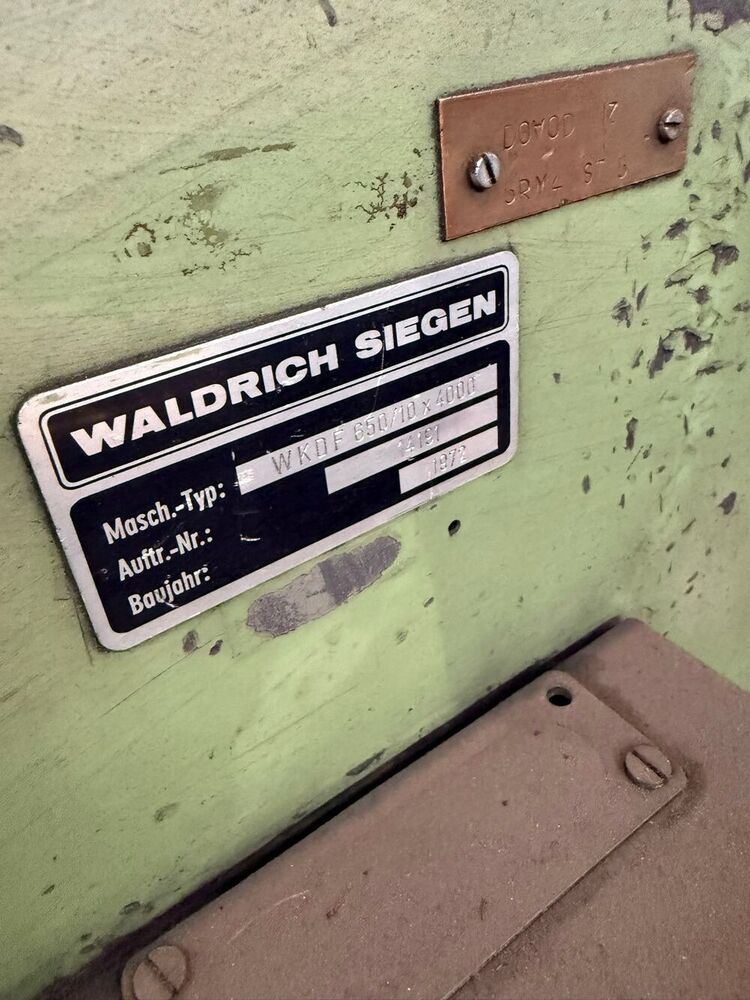

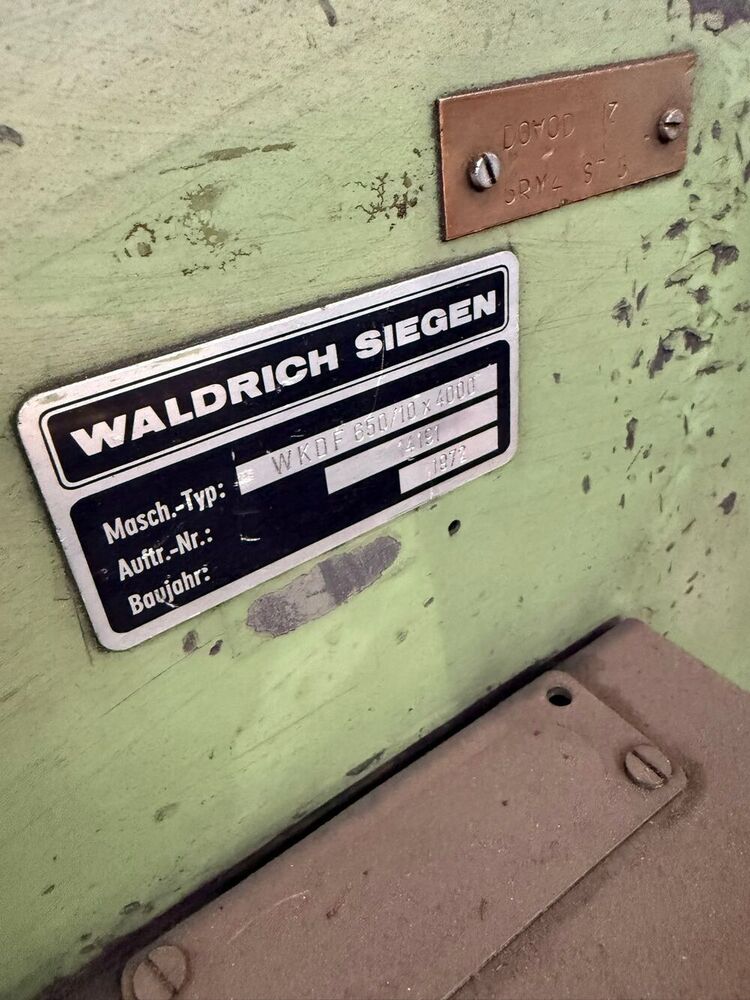

Used Lathe Machine Waldrich Siegen

Center Height: 400 mm

Max. Swing over bed: 800 mm

Max. turning diameter: 650 mm

Min. turning diameter: 200 mm

Max. turning length: 4000 mm

Max. workpiece weight: 10 tons

Center height: 400 mm

Faceplate diameter: 600 mm

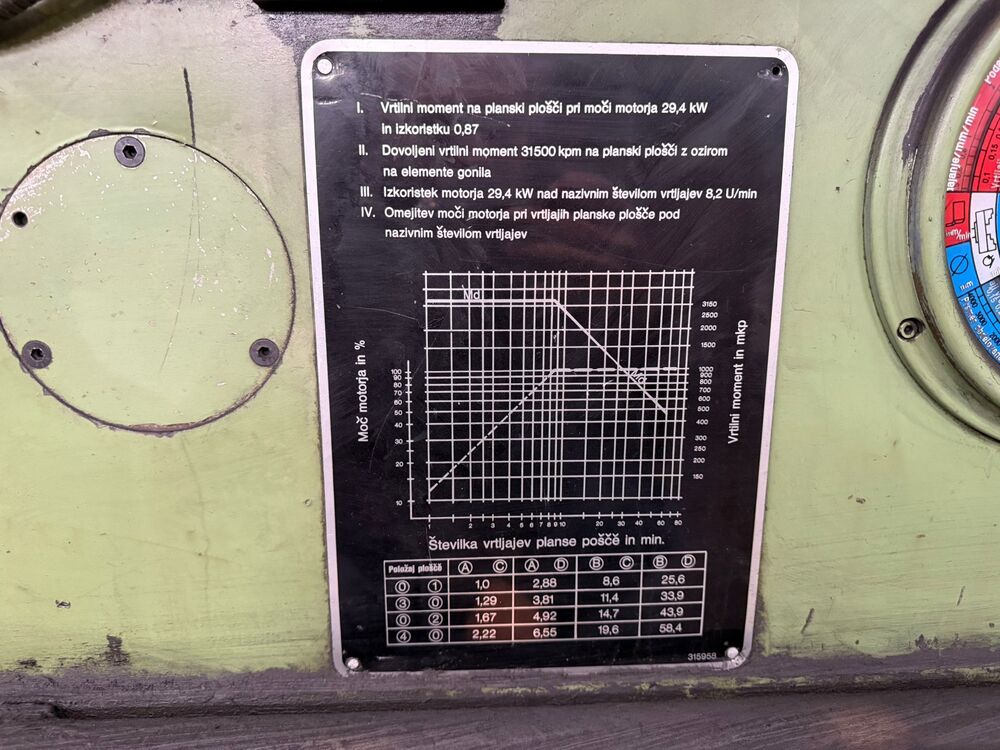

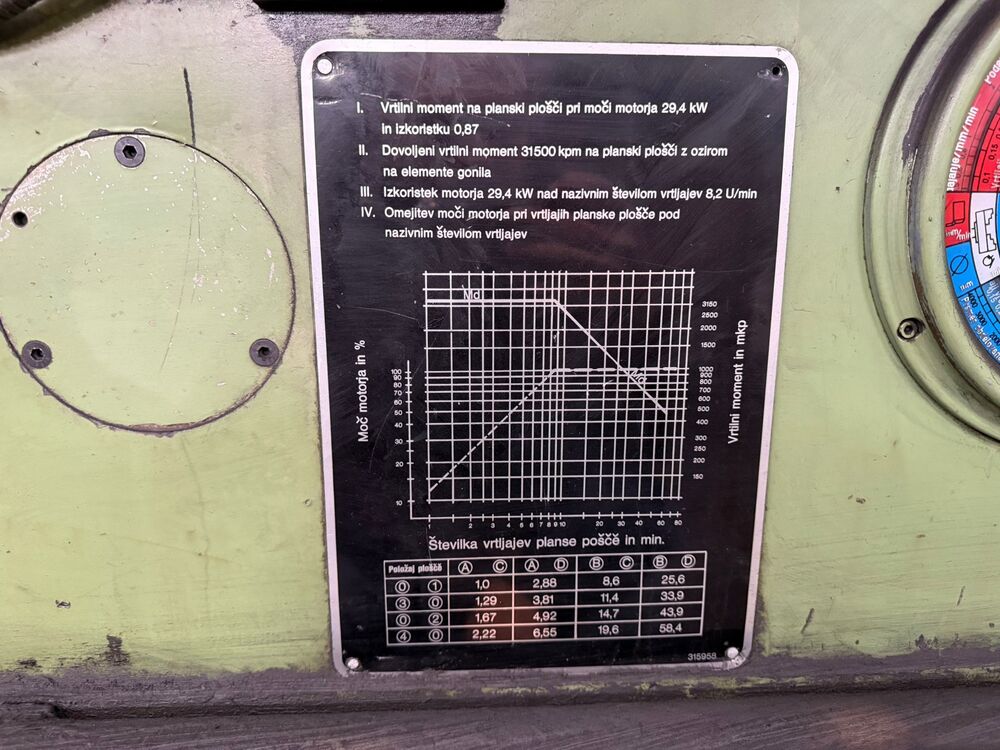

Speed: 1 - 58.4 rpm

Drive power: 45 HP

Tailstock

Exceptional Versatility and PerformanceThe lathes wide spindle speed range (20800 RPM), large chuck, and bed accommodate a variety of turning, facing, cutting, and threading tasks. Featuring both manual and automatic feed options, this equipment promotes efficiency and accuracy while supporting diverse industrial applications. Its sturdy construction ensures vibration-free operation and long-term durability.

Intuitive Controls and Safe OperationManual controls with integrated clutch and brake provide precision and safety during operation. The gearbox-driven main drive enhances torque and uninterrupted power transmission, while the stable floor-mounted structure and required foundation offer secure handling of heavy workpieces. The included coolant system maintains optimal cutting conditions throughout demanding processes.

Comprehensive Accessories and ValueSupplied with essential accessories such as a steady rest, tool holders, and change gears, this machine delivers value and adaptability in various machining scenarios. Its compatibility with both metric and inch threading expands its usability across global standards, making it an excellent choice for manufacturers and workshops requiring large-capacity, reliable production tools.

FAQs of used horizontal lathe machine:

Q: How is the horizontal lathe machine installed and what foundation does it require?

A: This lathe is floor-mounted and requires a solid, level foundation to support its weight of approximately 15,000 kg. Proper installation should be performed by qualified personnel to ensure stability and precision during operation.

Q: What workpiece sizes and applications is this lathe best suited for?

A: With a swing over bed of about 1000 mm, a bed length of 30005000 mm, and a chuck size up to 1000 mm, this machine effectively handles large and heavy workpieces. Its ideal for precision metal turning, facing, cutting, threading, and drilling operations in industrial settings.

Q: Where can this lathe be used and what industries benefit the most?

A: This heavy-duty lathe is suitable for metal fabrication workshops, manufacturing plants, industrial maintenance, and repair facilitiesespecially those needing high-precision turning of large components, such as energy, shipbuilding, automotive, and machinery sectors.

Q: What is the spindle speed range and how does it affect machining processes?

A: The spindle speed range is 20800 RPM, variable or stepped. This versatility lets operators choose the optimal speed for each material and operation, enabling both fine finishing and heavy roughing with ease.

Q: How are metric and inch threading operations performed on this machine?

A: The lead screw supports both metric and inch threading, allowing users to switch between standards conveniently. Change gears and manual controls simplify setup for accurate threading according to the jobs requirement.

Q: What accessories are included with the lathe and how do they enhance usage?

A: This lathe comes with a steady rest, tool holders, and change gears. These accessories add flexibility, supporting long or heavy workpieces and facilitating a range of turning and threading processes with stable operation.